Rubber to Metal Bonding

At CDJ Rubber, we are able to offer our customers excellent technical advice on the rubber to metal bonding process, from the design of your mould to the completion of your desired moulding. Our rubber to metal bonding mouldings can be created using premium quality natural rubber, SBR rubber, polybutadiene rubber, neoprene rubber, nitrile rubber, EPDM rubber, silicone rubber, and fluoroelastomers. At CDJ Rubber, we can mould your product to your personal specifications, and to any hardness range and standard you desire. We all sell pre-made standard rubber to metal bonding mouldings for your convenience.

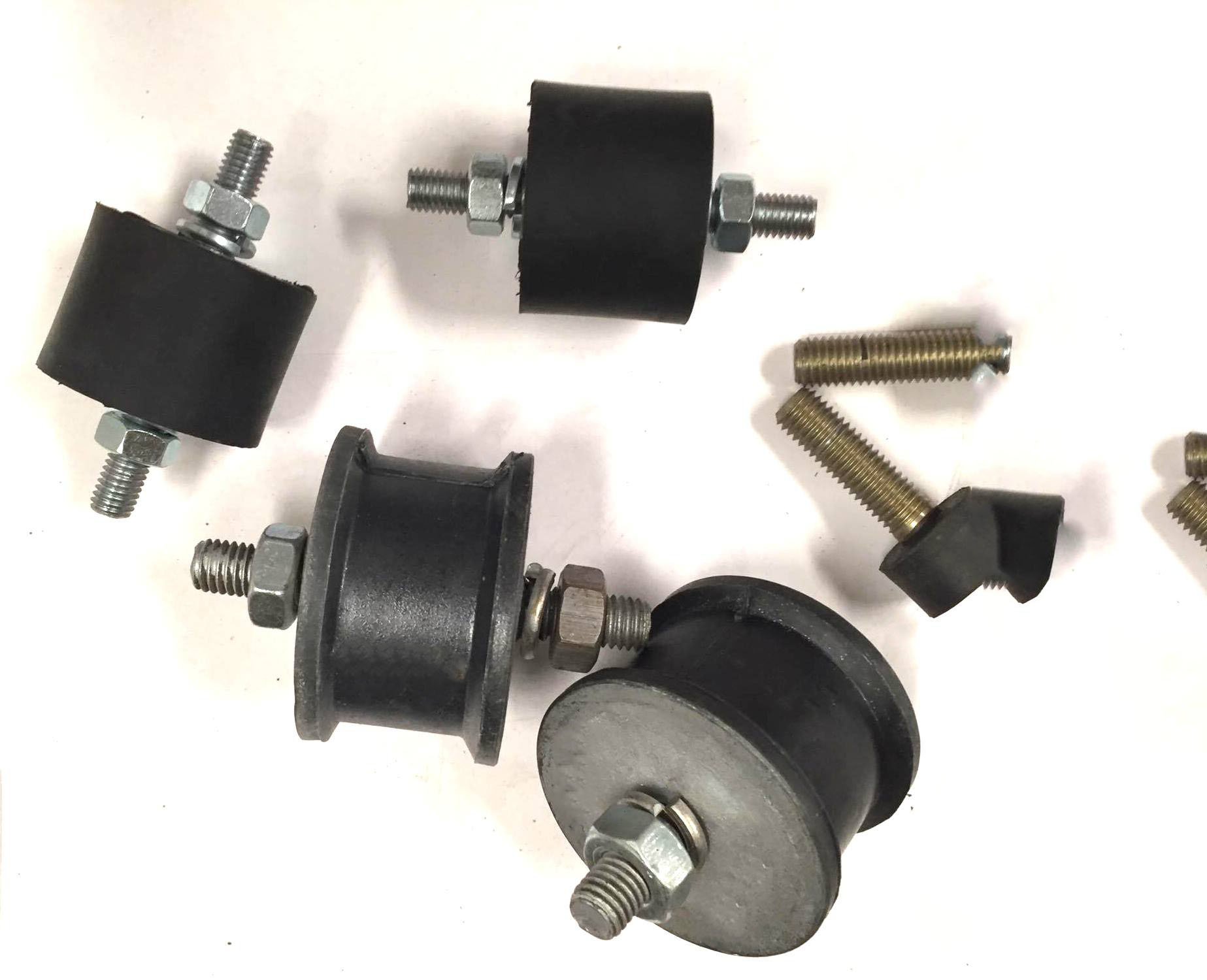

Rubber to metal bonding involves bonding rubber to a metal insert during the moulding process. Rubber to metal bonding mouldings are often used for shock absorbance, isolation of noise and vibration, sealing, comfort gripping, and friction dissipation, amongst other uses. Rubber to metal bonding is commonly used for the following products: seals, gaskets, conveyor belts, pedals, bearings and pad surfaces. They can also be used in components of plugs, rubber lined pipes and tanks, and electrical cables.

Our rubber to metal bonding products have a high heat, moisture and weathering resistance, enabling them to be durable in harsh conditions. Our rubber to metal bonding mouldings can be used in a number of industries, such as the aerospace, automotive, construction, manufacturing, electrical and medical industries.

At CDJ Rubber, we are committed to providing our customers with quality products, and so our rubber to metal bonding is carried out using only premium quality virgin polymers; we do not use rubber dust, rubber crumbs or recycled rubber in any of our products. We also aim to offer fantastic service to our customers, and so we have fast delivery times from our factory on the Central Coast, NSW. We deliver our rubber to metal bonding products Australia wide, including the Central Coast, Hunter, Sydney and Newcastle Regions.

Features of rubber to metal bonding:

- Shock absorption

- Noise isolation

- Vibration isolation

- Sealing

- Friction dissipation

- Comfort gripping

- Oxidation resistant

- Weathering Resistant

- High heat resistance

Applications of rubber to metal bonding:

- Aerospace industry

- Healthcare industry

- Construction

- Transport industry

- Mining industry

- Vehicle suspension systems

- Equipment parts

- Machinery parts

- Plumbing

- Home use